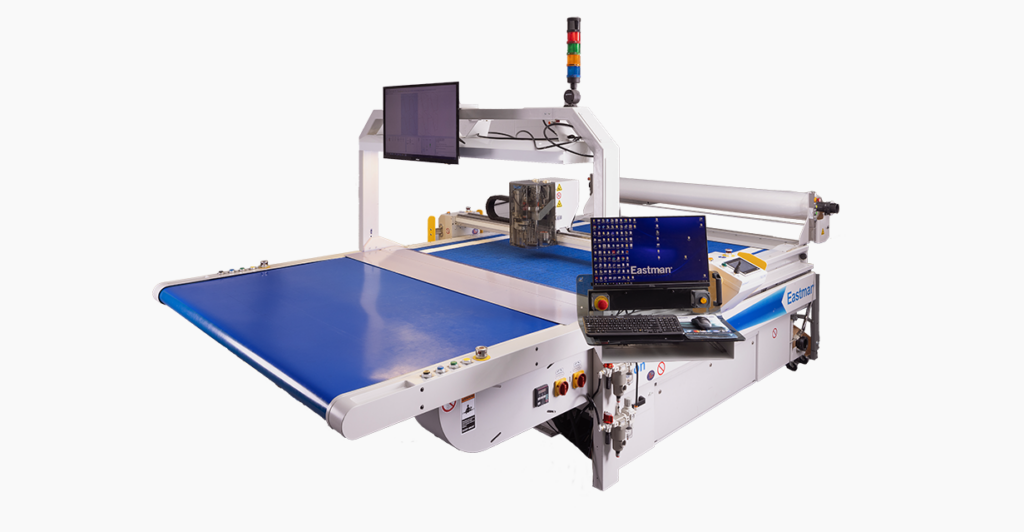

Talon Multi-Ply

SKU: Talon

View Product on Marketing Website

The Eastman Talon Multi-Ply is engineered and manufactured in the USA to automatically pull stacked material plies from the spreading table to a modular, bristle-block conveyor bed for reciprocating knife cutting of patterns. Precise system operations with state-of-the-art motion control communications offer an industrial-strength solution. The Talon 25 can cut up to 1.18 in. (3 cm) of compressed material goods, while the Talon 75 has the capabilities to cut up to 3 in. (7 cm) of compressed material goods.

The Talon has been engineered to meet the demands of clients in growing market segments like industrial fabrics and composites industries; customers cutting traditional -as well as- modern technical materials like kevlar, fiberglass, nonwoven polyesters, foam-backed vinyl and other industrial fabrics.

Categories

Automated Cutting, Automated Cutting Systems

Product Attributes

| Cutting Area Width |

Talon 25: 78 inches (2.0 m) |

|---|---|

| Overall Machine Width |

111 inches (2.84 m) |

| Cutting Area Length |

5.5 ft. (1.68 m) |

| Overall Machine Length |

13 ft. (3.96m); 4 ft. (1.22m) unloading conveyor |

| Drive System |

Dual-X Axis, Y-Axis & Theta Axis. |

| Max. Thickness of Compressed Material |

Talon 25: 1.18 in. (3 cm) |

| Electric - Control Power |

208/230/380/460/575V, 3 ph, 50/60 Hz, 9.0 kVA |

| Electric - Vacuum Blower |

208/230/380/460/575V, 50/60 Hz, 25 HP, VFD control |

| Pneumatic |

90 psi (6.2 bars), 18 cfm |

| Maximum Cutting Speed |

Up to 40 in./sec (101.6 cm/second) – material dependent |

| Maximum Conveyor Speed |

8 in./sec. (20.3cm/min) |

| Maximum Acceleration |

1.0 g |

| Sound Level |

<76 dB(A) |

| Operating Temperature |

55 – 100°F (12 – 37°C) |

| Humidity |

20-80% (non-condensing) |